When you pick up your phone, take apart an auto part, or look at a home appliance casing, you might not realize that hidden inside these seemingly ordinary plastic products lies a kind of “invisible rebar” — glass fiber (GF). From PP + 20% GF to PA + 60% GF, these reinforcing fibers quietly support the plastic matrix, much like steel bars inside concrete.

Today, let’s uncover the mystery of long glass fibers, short glass fibers, and flat glass fibers, and see how they transform plastics into materials that achieve the perfect balance of strength and flexibility.

Glass Fiber: The “Reinforcement Code” of Plastics

What makes glass fiber the “golden partner” of engineering plastics lies in the fiber–resin synergy, which compensates for the inherent weaknesses of pure plastics:

1. Mechanical Reinforcement: Like adding a hidden skeleton to plastics, tensile strength can be improved by 20%–100%, while impact toughness can even approach the level of metals.

| Material |

Tensile Strength

|

Testing Standard

|

| Neat PP Resin | 30 MPa |

ASTM D-638

|

|

PP Short Glass Fiber Reinforced |

90 MPa |

ASTM D-638

|

| PP Long Glass Fiber Reinforced | 150 MPa |

ASTM D-638

|

The material data varies across different brands.

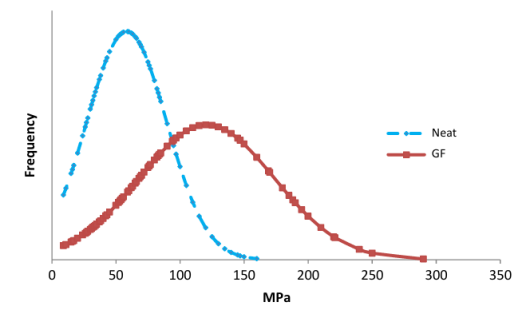

This chart compares the strength distribution of neat polymer (blue dashed line) and glass fiber reinforced polymer (red line). The neat polymer shows lower strength values concentrated around 70–90 MPa, while the glass fiber reinforced polymer exhibits a broader distribution with much higher strengths, extending up to around 300 MPa. This indicates that glass fiber reinforcement significantly improves the material’s mechanical performance.

2. Deformation resistance: suppresses resin shrinkage, making products less prone to warping under high temperature and stress, with a shrinkage rate controllable to as low as 0.15%.

3. Cost balancing: compared with pure engineering plastics, fiber-reinforced materials can achieve high performance at lower cost. For example, using long glass fiber PA to replace metal in automotive parts reduces weight by 58% while cutting costs by 30%. However, different forms of glass fiber bring very different “buffs” to plastics. The right choice can double product performance, while the wrong one may lead to issues such as fiber exposure and brittleness.

Type of fiber: long, short, or flat

The most commonly used glass fibers are long glass fiber, short glass fiber, and flat glass fiber. They differ significantly in morphology, performance, processing methods, and application scenarios, which is also reflected in their structural characteristics:

Glass Fiber Comparison Table

| Type | Length Range | Morphological Characteristics | Core Advantages |

|---|---|---|---|

| Long Glass Fiber | 5–25 mm (commonly 6–12 mm) | Continuous filaments, high integrity | Strength champion, excellent fatigue resistance |

| Short Glass Fiber | 0.1–1 mm (commonly 0.2–0.5 mm) | Short cut segments, easy to disperse | Processing-friendly, balanced performance |

| Flat Glass Fiber | 0.5–5 mm (customizable) | Flat ribbon-like, large surface area | Smooth surface, warp-resistant expert |

Long glass fibers are like “continuous steel bars,” forming a continuous network within the resin and efficiently transmitting stress, which is why their impact strength is 50%–100% higher than that of short glass fibers. Short glass fibers resemble “broken steel slag”: they are evenly dispersed but limited in length, making them suitable for applications that require high isotropy. Flat glass fibers are like “thin steel sheets,” with a thickness of 3–10 μm and a width of 50–200 μm, giving them 3–5 times more contact area with the resin than round glass fibers, directly enhancing surface smoothness by one grade.

Performance Showdown: Who’s Your “Ideal Type”?

When choosing glass fibers, focus on the following key performance dimensions:

1. Appearance

Flake Glass Fiber-Filled PC:

Thanks to its flat ribbon-like structure, the contact area with the PC resin is 3–5 times larger than that of the same weight of round glass fibers. This creates a smoother fiber-resin interface. Combined with a special drawing process that reduces surface roughness, the surface gloss of the molded part (measured at a 60° angle) can reach 80–90, close to a mirror-like finish of pure PC, with almost no visible fiber float.

Short Glass Fiber-Filled PC:

Short fibers are evenly dispersed, causing only mild light scattering. However, the round fiber cross-section still produces minor reflections at the fiber-resin interface. Surface gloss is slightly lower than flake glass fiber, usually around 70–80. Fiber float visibility requires stricter control of the molding process.

Long Glass Fiber-Filled PC:

Long fibers (6–12 mm) tend to form local agglomerations during processing. Due to the “skeleton effect,” tiny gaps exist at the fiber-resin interface, causing diffuse reflection of light in these areas. Surface gloss is only 50–60, resulting in a slightly matte finish. This type is more suitable for functional parts such as engineering machinery housings, where performance is prioritized over appearance.

2. Inner Strength: Mechanical Performance Study

Long Glass Fiber is undoubtedly the “strength champion.” Data shows that at the same content, PA reinforced with long glass fibers has 20–30% higher tensile strength than short glass fiber composites, and notch impact strength is 50–60% higher, making it especially suitable for long-term load-bearing components such as automotive bumpers and wind turbine blades. LFT-G’s Verton long glass fiber composites can even maintain impact strength at -40°C, a performance level difficult for short glass fibers to achieve.

Short Glass Fiber excels in “balance.” Although its strength is slightly lower, it offers good isotropy, meaning the part’s performance is uniform in all directions. This makes it ideal for precision components such as gears and connectors.

Flake (Flat) Glass Fiber improves lateral toughness slightly. For example, using flake glass fiber to reinforce Si-PC blends for smartphone housings can increase drop resistance by 40% while avoiding defects such as fiber protrusion.

3. Dimensional Stability: The Key to Warpage Control

Long Glass Fiber: Its “skeleton effect” firmly restrains the resin, reducing shrinkage along the flow direction to as low as 0.15%. However, shrinkage differences in the perpendicular direction can be significant, making large flat panels prone to warping.

Short Glass Fiber: Shrinkage is more uniform, making it suitable for small to medium-sized parts.

Flake (Flat) Glass Fiber: Thanks to its flat structure, it provides more balanced control over in-plane shrinkage, making it an ideal choice for automotive interior panels.

4. Processing Difficulty

Long Fibers: They tend to tangle, requiring high-performance injection molding equipment. Molds need large runners and gates (≥3 mm), and complex parts may require low-pressure processes such as Injection Compression Molding (ICM), Structural Foam Molding (SFM), or Gas-Assisted Injection Molding (GAIM). Otherwise, fiber breakage can drastically reduce performance.

Short Glass Fiber and Flake (Flat) Glass Fiber: These are easier to process with mature, established methods. They can be molded on standard injection machines, and high-flow grades can even fill thin walls down to 0.5 mm. Flake glass fiber, thanks to its good surface appearance, can achieve better aesthetics than short glass fiber without the need for higher mold temperatures.

Application Scenarios: Putting the Right Glass Fiber in the Right Place

There is no “best” glass fiber, only the most suitable choice. Let’s look at the main arenas for different types of glass fibers:

Long Glass Fiber: The “heavy-duty champion” of industrial applications.

Components such as automotive chassis brackets, engineering machinery housings, and ski binding fixtures that must withstand long-term impacts and loads are best served by long glass fibers. Long glass fiber composites used in cable brackets can last 10 years underground without corrosion, completely solving the rust problems of metal brackets. Long glass fiber-reinforced plastics are also ideal for automotive pedals.

Short Glass Fiber: The “cost-performance king” of consumer goods.

Parts such as washing machine drums, air conditioner compressor brackets, and electronic connectors require basic strength but are cost-sensitive. Short glass fiber-reinforced materials are perfect for these, for example, 30% short glass fiber PA66 gears, which are wear-resistant yet affordable.

Flake (Flat) Glass Fiber: Combines appearance and strength.

Components like smartphone housings, laptop A-side panels, and automotive interior panels need both drop resistance and aesthetics. Flake glass fiber provides a mirror-smooth surface while maintaining sufficient strength even in thin walls of 0.8 mm.