Aluminum nitride (AlN) ceramici s an advanced ceramic material serving as a key thermal management solution in the semiconductor and 5G industries. Its exceptional thermal conductivity (170-230 W/mK) and reliable electrical insulation properties heavily depend on one core characteristic: sintering activity. Simply put, sintering activity determines whether high-purity AlN powder can achieve high densification efficiently at elevated temperatures to form high-performance ceramics for electronic packaging, heat spreaders, and substrate applications.

What is Sintering Activity?

Sintering activity refers to the ability of a ceramic powder to form a dense structure during heat treatment. Powder with high activity enables low-temperature sintering, achieving high density in shorter timeframes, significantly reducing production costs while enhancing thermal performance and mechanical reliability.

Three Key Factors Influencing Sintering Activity

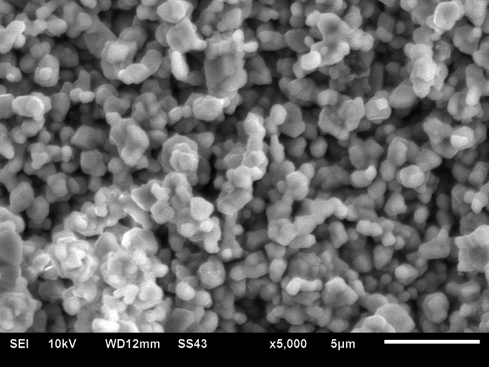

1. Powder Particle Size

Fine powder with submicron particles provides larger specific surface area and higher surface energy, resulting in stronger sintering drive and improved microstructure development.

2. Oxygen Content Control

Excessive oxygen content leads to alumina formation, creating interfacial barriers that degrade thermal conductivity and hinder densification process. Maintaining low oxygen levels is critical for high thermal conductivity AlN.

3. Sintering Additives

Yttria (Y₂O₃) additives react with surface oxides to form liquid phase sintering, enhancing mass transport and pore elimination. This enables pressureless sintering of high-density AlN ceramics with optimized grain boundary engineering.

How to Optimize Sintering?

1、Use high-purity AlN powder with controlled particle size distribution

2、Implement atmospheric sintering under nitrogen environment

3、Apply sintering aids for microstructure control

4、Utilize non-oxide additives for thermal conductivity enhancement

5、Optimize sintering profile for cost-effective production

Conclusion

Sintering activity is a critical material property determining the end-performance of AlN ceramics in power electronics, LED packaging, and RF applications. Mastery of sintering technology enables manufacturers to produce high-thermal-conductivity substrates with superior mechanical strength and reliability performance, positioning AlN as the material of choice for next-generation thermal management solutions.

About Xiamen Juci Technology Co., LTD

Xiamen Juci Technology Co., Ltd. is a leading Chinese manufacturer of aluminum nitride (AlN) powder, utilizing the carbothermal reduction method for its production. The aluminum nitride powder produced through this process exhibits exceptionally high sintering activity and ultra-high purity. Such powder enables the fabrication of highly dense aluminum nitride ceramics, providing superior thermal management solutions for 5G communications, semiconductors, and other advanced industries.

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com.