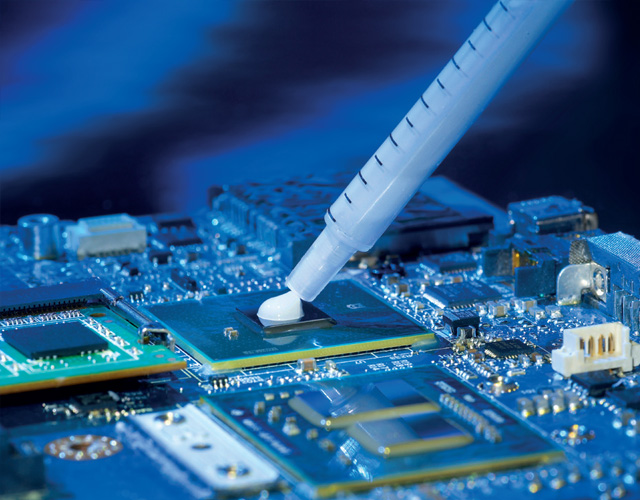

With the miniaturization and high degree of integration of electronic products and their devices, the problem of heat dissipation has become an important bottleneck restricting the development of electronic technology, which determines the effectiveness of heat dissipation of thermal interface materials, such as thermal conductive composite materials are more and more attention.

At present, commercial thermally conductive composites are generally made of organic materials and thermally conductive filler composite. As the thermal conductivity of organic materials is very low, generally less than 0.5W/m-K, so the thermal conductivity of thermally conductive composite materials is mainly determined by the thermal conductivity filler.

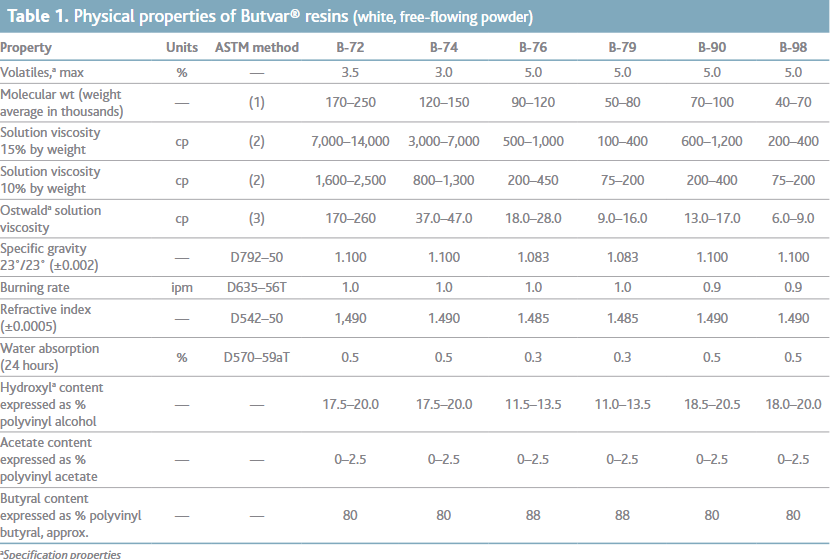

The thermal conductivity of common polymer matrix and thermally conductive fillers The most widely used fillers on the market are oxide fillers represented by alumina and so on, but the intrinsic thermal conductivity of alumina is only 38~42W/m-K, which is limited by the fact that it will be very difficult to prepare thermally conductive composites to meet the market demand for future heat dissipation materials.

In contrast, the theoretical thermal conductivity of AlN is as high as 320W/m-K, and it has excellent properties such as small coefficient of thermal expansion, good insulating properties, low dielectric constant, and matching with the expansion coefficient of silicon, so the preparation of thermally conductive composites by using AlN powder as a filler has been highly sought after in recent years.

A key problem must be solved

Although the comprehensive performance of aluminum nitride is much better than alumina, beryllium oxide and silicon carbide, and is considered to be the ideal material for highly integrated semiconductor substrate and electronic device packaging, but it has an unpleasant place, that is, it is easy to absorb water in the air hydrolysis reaction occurs, so that the surface of the coating on a layer of aluminum hydroxide film, resulting in the interruption of the thermal conductivity pathway and the phonon transmission is affected, and the filling of the large content of its polymer viscosity will increase greatly, not conducive to molding and processing. The viscosity of the polymer is greatly increased by its large filling content, which is unfavorable to the molding process.

In order to overcome the above problems, surface modification of the thermally conductive particles is necessary to improve the interfacial bonding between the two. At present, there are two main methods to modify the surface of inorganic particles, one is the surface chemical reaction method, which is a small molecule such as coupling agent adsorption or reaction on the surface of inorganic particles. The other is the surface grafting method, which is the grafting reaction between the polymer monomer and the hydroxyl group on the surface of the inorganic particles.

Currently commonly used are coupling agent surface modifications such as silane and titanate coupling agents and other types of surface treatment agents. Surface grafting offers greater flexibility than surface chemical reaction methods in that it allows the selection of monomers and grafting reaction processes that satisfy the conditions based on different characterization needs.

Influence of particle size and shape on thermal conductive materials

The effect of aluminum nitride particle size on the thermal conductivity of polymer composites is mainly manifested in two aspects. On the one hand, the small specific surface area of the large-size filler, the smaller the area of the interfacial layer it forms, i.e., the smaller the thermal interfacial resistance, the higher the thermal conductivity obtained theoretically; however, the stacking density of the small-size filler is higher, so that it can effectively reduce the voids and improve the thermal conductivity.

Isn't this a contradiction? Is it better to have a larger or smaller particle size? In fact, the aluminum nitride filler particle size is too large or too small are not good, too large to lead to the stacking density is small and uneven distribution, thermal conductivity decreases. Particle size is too small, resulting in more interfaces, thermal resistance, and small particle size filler is easier to gather, causing the viscosity of the system to rise, resulting in the existence of voids in the polymer, making the polymer mechanical and thermal properties of the decline.

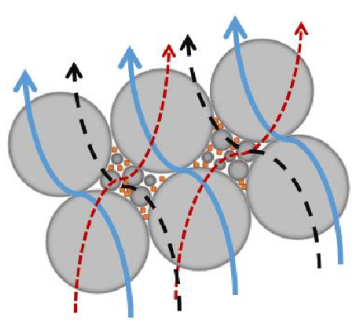

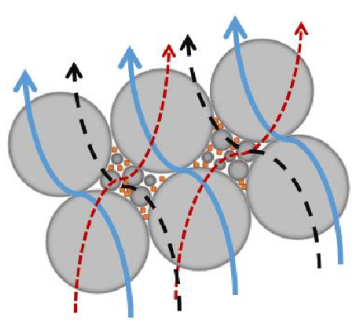

Therefore, we require that the particle size be "neither too large nor too small", but this is difficult to meet the ideal requirement.So people thought of a good way - the use of different particle size particles compounding. Selected particles of different sizes as a mixture of filler filled into the matrix material, the large particles constitute the main thermal pathway, the small particles will be filled into the gap between the large particles in order to form a richer thermal conductivity of the network, so as to realize the composite material thermal conductivity improved.

Different sizes of thermally conductive AlN filler particles grading schematic again, the shape of the filler (whiskers, fibrous, flaky, spherical) on the thermal conductivity of the material has an impact on the formation of thermally conductive pathway is: whiskers> fibrous> flaky> spherical, but the formation of spherical filler packing density is the largest in the high filler, does not lead to a sharp increase in the viscosity, but in the industry is the most widely used. In addition, the processing process also affects the application effect of aluminum nitride in polymer thermal conductive materials, this is because the processing process affects the dispersion and distribution of fillers in the matrix, the dispersion state of fillers in the matrix will affect the formation of thermal conductive pathways in the composite material, thus affecting the thermal conductivity of the composite material. According to the different forms of polymer composite, the processing and molding methods can be divided into solution mixing, powder mixing, melt mixing three ways, and its effect on the improvement of thermal conductivity presents the following characteristics: powder mixing > solution mixing > melt mixing.

About Xiamen Juci Technology Co., Ltd.

Xiamen Juci Technology Co., Ltd. is a high-tech enterprise dedicated to the R&D, production, and sales of high-performance aluminum nitride (AlN) materials. As a leading AlN filler supplier, we specialize in delivering premium Aluminum nitride heat dissipation products and tailored solutions for industries such as electronics, semiconductors, and aerospace.

One of our key strengths is effectively mitigating the hydrolysis issue of AlN, ensuring superior material stability and performance. With exceptional product quality and customer-centric service, Xiamen Juci has earned the trust of clients worldwide.

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com