Aluminum nitride (AlN) ceramics are widely used in electronic packaging and heat dissipation due to their excellent thermal conductivity. However, impurities and sintering conditions significantly affect their performance. This article discusses key approaches to improving AlN's thermal conductivity, including powder purification, sintering aids, process optimization, and prolonged sintering.

(1) Controlling the Quality of AlN Powder and Reducing Oxygen Impurity Content

Improving the synthesis method of AlN powder to produce high-purity powder with a particle size below 1 μm and an oxygen content of 1% is a prerequisite for preparing high-thermal-conductivity AlN ceramics. Additionally, for AlN powder containing sintering aids, introducing an appropriate amount of carbon can reduce and carburize the oxides on the AlN powder surface during the sintering process before densification, thereby enhancing the thermal conductivity of AlN ceramics. From this perspective, AlN powder prepared by the carbothermal reduction method may be more conducive to improving the thermal conductivity of AlN ceramics.

(2) Selecting Appropriate Types and Amounts of Sintering Additives

Extensive research has shown that rare-earth metal oxides and fluorides, alkaline-earth metal oxides and fluorides, etc., can serve as sintering aids to improve the thermal conductivity of AlN. Sintering aids react with alumina in AlN to form aluminate liquid phases, facilitating liquid-phase sintering and densification of the green body. On the other hand, sintering aids can reduce the oxygen content in the AlN lattice while enhancing contact between AlN particles, thereby improving thermal conductivity. However, the amount of additives must be appropriate—excessive amounts increase impurity content and impair thermal conductivity, while insufficient amounts fail to serve as effective sintering aids. As mentioned earlier, recent studies have shown that composite additives are more effective than single additives in enhancing thermal conductivity while also lowering the sintering temperature.

The effectiveness of additives in improving thermal conductivity has been confirmed by numerous experiments. Introducing suitable additives is currently a widely adopted method. However, there is no unified conclusion regarding the selection and combination of additives, their optimal amounts, or the methods of addition, necessitating further in-depth and systematic exploration.

(3) Optimizing Sintering Processes

For AlN ceramics, slow heating during sintering is more advantageous than rapid heating, as it not only reduces deformation but also improves the densification of the green body, thereby enhancing the performance of AlN ceramics.

The sintering process also involves an optimal sintering temperature. If the temperature is too high, excessive grain growth occurs, the grain boundary phase increases, and densification decreases, negatively impacting thermal conductivity.

Appropriately extending the sintering time can further purify the crystal lattice, promote grain growth, and significantly reduce porosity, thereby increasing thermal conductivity.

Generally, sintering in a reducing atmosphere under nitrogen protection can reduce oxygen impurities in AlN through carbothermal nitridation and reduction, which is beneficial for improving thermal conductivity. Pressure sintering significantly enhances the sintering performance of AlN and reduces the amount of sintering aids required. Increasing pressure improves the densification of AlN, all of which contribute to better performance of AlN ceramics. Additionally, the powder-bed method also affects the thermal conductivity of AlN ceramics.

(4) Prolonging Sintering Time

In addition to introducing sintering aids and optimizing sintering processes, extending the sintering time can also improve the thermal conductivity of AlN ceramics. For example, annealing in a reducing atmosphere can remove oxygen and secondary phases from AlN. Nakano et al. used a similar method, heat-treating sintered AlN (with Y₂O₃) in a reducing nitrogen atmosphere at 1900°C. After 20 hours, the thermal conductivity reached 220 W/m·K, and after 100 hours, it increased to 272 W/m·K.

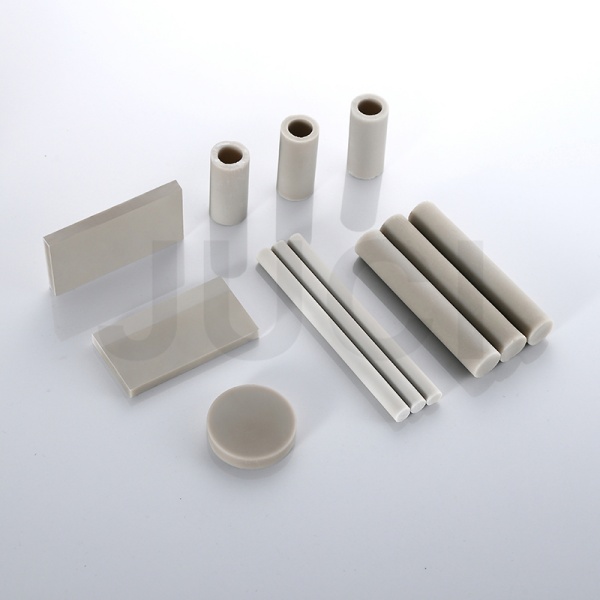

About Xiamen Juci Technology

Juci Technology, with its high-purity raw materials, composite additive technology, precise sintering process and flexible customization capabilities, has become one of the few domestic enterprises capable of stably mass-producing high thermal conductivity AlN ceramics, especially suitable for the demands of high-end fields such as high-power leds, IGBT modules and aerospace.

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com