The composition of TC4 titanium alloy is Ti-6AI-4V, which belongs to the (a+β) type titanium alloy. It has good comprehensive mechanical properties, high specific strength, excellent corrosion resistance, good biocompatibility, and is widely used in aerospace, petrochemical, biomedical and other fields. This article selects the plasma rotating electrode method to prepare titanium alloy powder, and discusses the spheroidization mechanism of titanium alloy powder. The evolution law of its microstructure is explored, and the main heat treatment methods are discussed, providing necessary theoretical basis for the application of TC4 titanium alloy in 3D printing technology.

2.1 Experimental Materials and Methods: TC4 alloy powder was prepared by plasma rotating electrode atomization method, and its chemical composition was analyzed by instruments, as shown below.

|

Al

|

Fe

|

V

|

C

|

N

|

Si

|

O

|

H

|

Ti

|

|

6.25

|

0.27

|

3.92

|

0.1

|

0.006

|

0.10

|

0.12

|

0.005

|

89.23

|

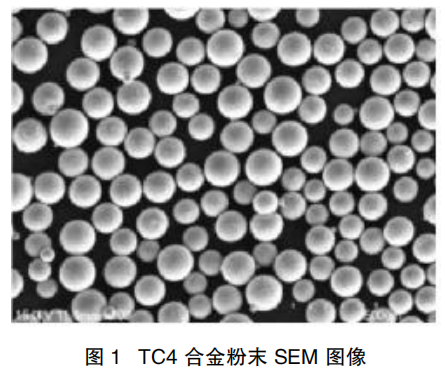

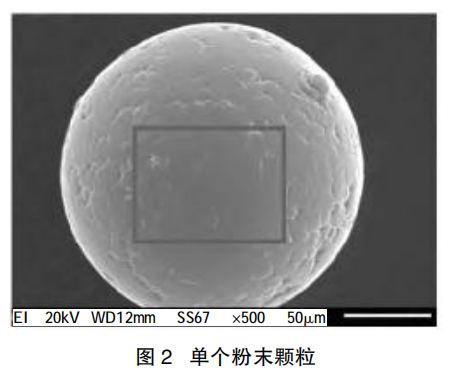

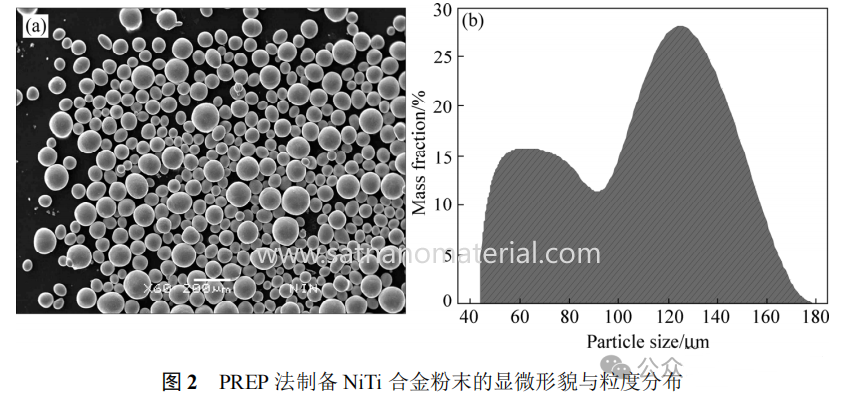

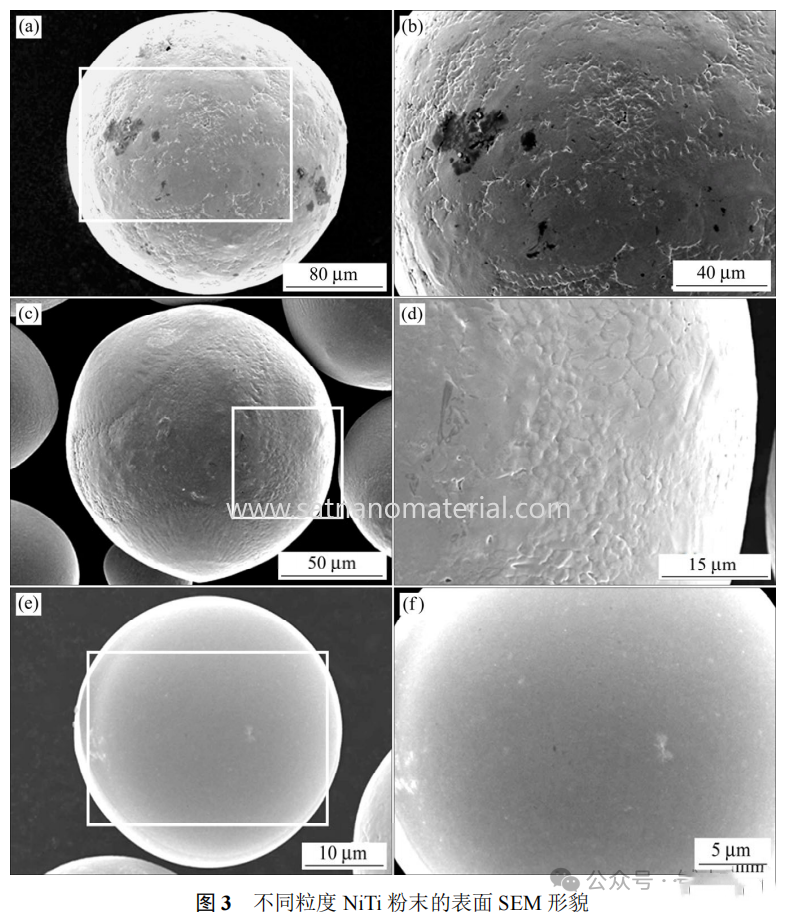

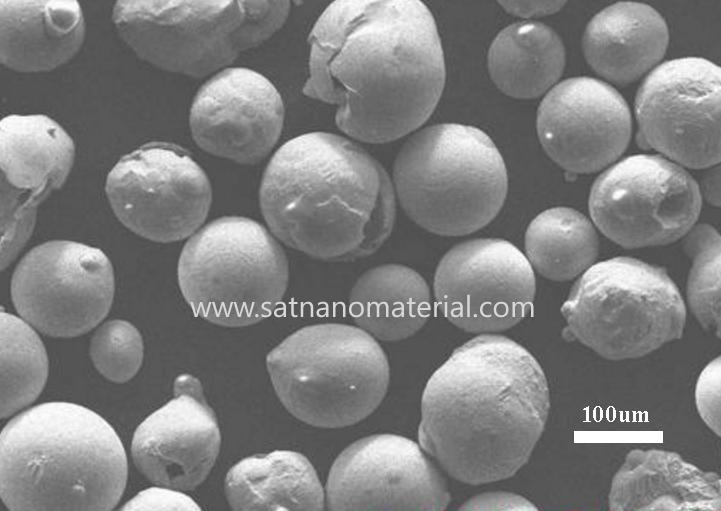

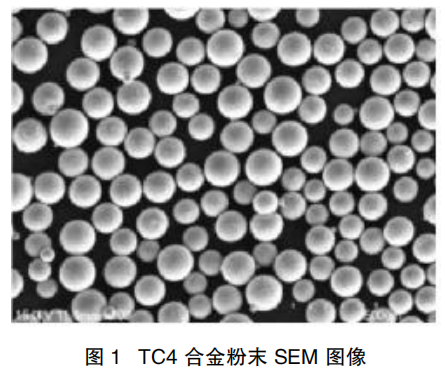

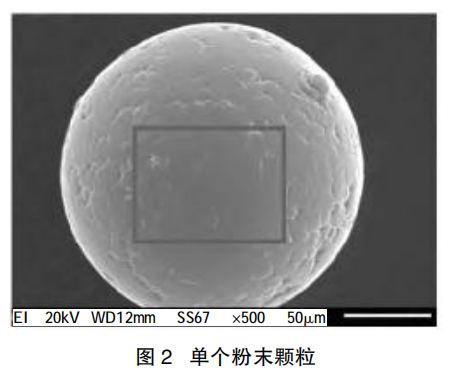

According to the table, the H, N, and O content in the powder is relatively low, which meets the requirements for printing high-performance products. The shape of the powder particles prepared by this process is very close to spherical, with a smooth surface, good flowability, and no excessive impurities. The SEM image observed under a scanning electron microscope is shown in Figure 1, and the individual powder particles are shown in Figure 2. Through observation, when the geometric shape of TC4 titanium alloy powder particles is spherical, the formability is good, while elliptical powder has poor flowability and formability. Spherical titanium alloy powder has good flowability during laser 3D printing preparation.

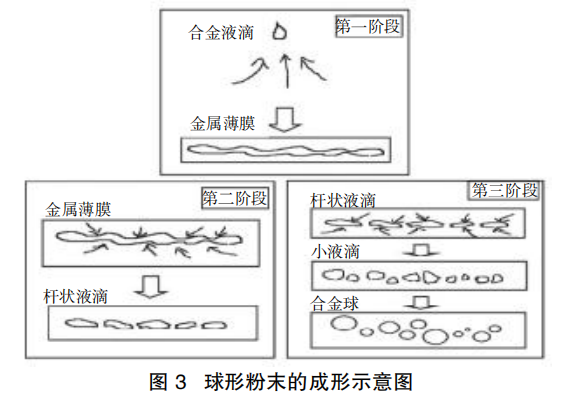

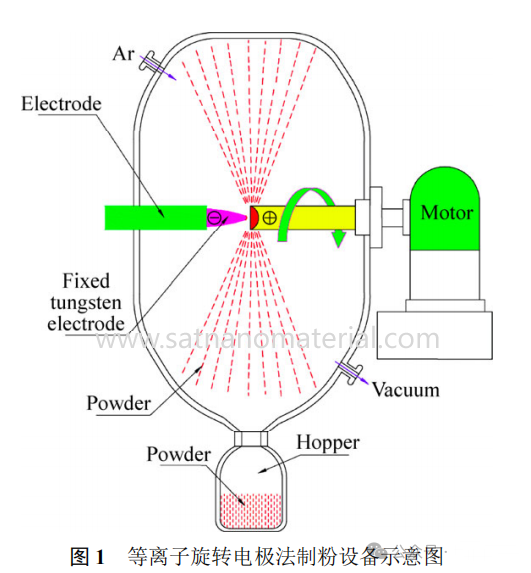

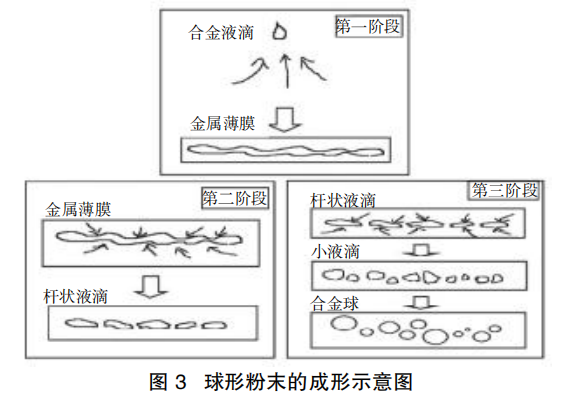

2.2 Experimental Results and Analysis 2.2.1 Ball Forming Mechanism of TC4 Titanium Alloy Powder In 3D printing technology, metal powder material is the raw material for metal 3D printing, and its basic properties have a significant impact on the quality of the final product formation. It is also one of the material basis and key elements for achieving rapid prototyping. The TC4 alloy powder prepared by plasma rotating electrode atomization method has a particle shape that is very close to spherical, with a smooth surface and good flowability. The mechanism of powder balling mainly consists of three processes, as shown in Figure 3. In the first process, the molten alloy droplets are impacted by high-speed airflow, causing them to grow into a wavy liquid film and move away from the gas center at high speed; In the second process, due to the pressure, the elongated alloy droplets are unstable. Under the surface tension of the liquid, they are then blown and broken, forming elliptical droplets; In the third process, the elliptical droplet continues to break again under the action of air pressure and liquid surface tension, and is segmented into several small droplets. Under the action of surface tension, the droplet tends to shrink into a spherical shape during the descent process, and the cooling accelerates, immediately solidifying into a spherical shape.

This experiment can obtain TC4 titanium alloy particle sizes mainly distributed in the range of 50-160 μ m by controlling the relevant parameters of the experiment. The particle size distribution is narrow and meets the requirements of 3D printing.

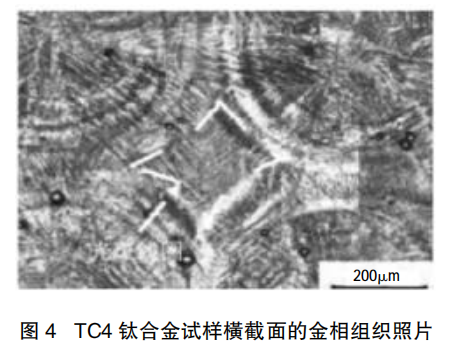

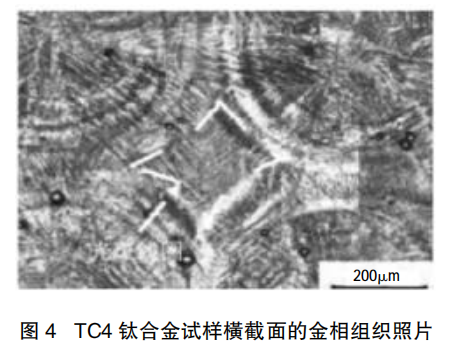

2.2.2 Microstructure of TC4 Titanium Alloy Sample The metallographic structure of the cross-section of the TC4 titanium alloy sample is shown in Figure 4. When the ion beam acts on the TC4 titanium alloy powder, a circular molten pool is formed. Within the molten pool, the temperature gradually decreases from the center to the edge, showing a Gaussian distribution. The difference in temperature results in varying degrees of melting of TC4 titanium alloy powder, with powders at lower temperatures in the edge region remaining unmelted or insufficiently melted, leading to differences in grain microstructure and size between the melt pool and the edge region. The use of pulse dot mode for metal powder cladding can reduce the influence of temperature gradient on the heat affected zone. When the latter heat source acts on the alloy powder, it also supplements energy to the edge area of the previous spot for remelting. After obtaining the energy, the grains continue to grow along the direction of energy absorption.

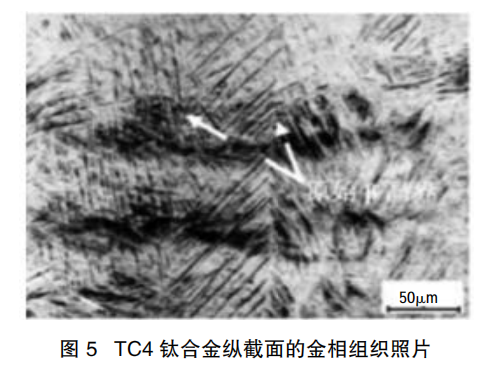

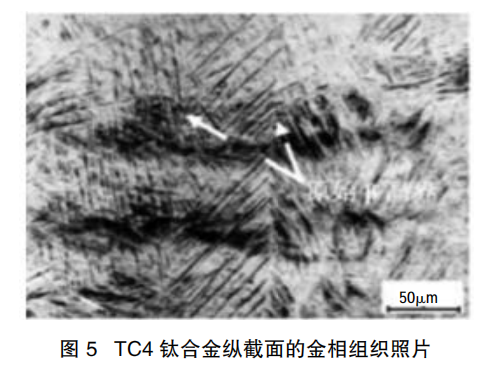

The metallographic structure photo of the longitudinal section of TC4 titanium alloy sample is shown in Figure 5. Through metallographic microscope observation, the microstructure is coarse β - columnar products. As shown in Figure 5, the grain boundaries can be clearly observed, and the columnar crystals grow along the stacking layer direction, with different growth directions. The growth stops at the β - columnar crystal boundary, and at the same time, the columnar crystals far away from the substrate continue to grow epitaxially, with grain growth phenomenon. After analysis, it was found that the temperature generated during the preparation of TC4 alloy by 3D printing has an impact on the microstructure of titanium alloy. When some of the alloy powder is melted by ion beam, the front part of the alloy is reheated. However, the beta phase self diffusion coefficient of TC4 alloy is relatively large, and smaller energy can promote grain growth. Therefore, columnar crystals are prone to growth and overheating during reheating.

Therefore, controlling the energy of the heat source can effectively alter the microstructure of TC4 alloy.

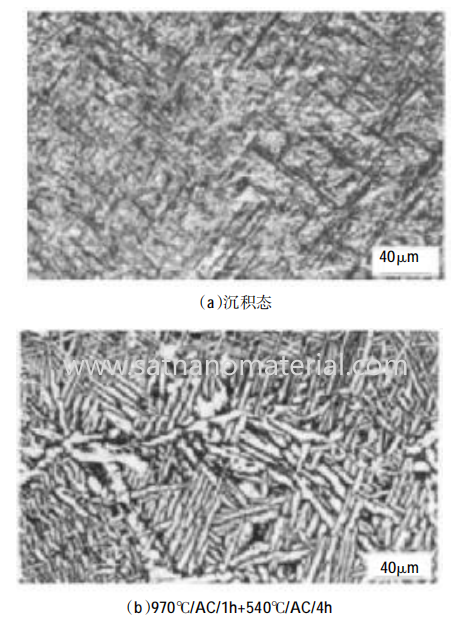

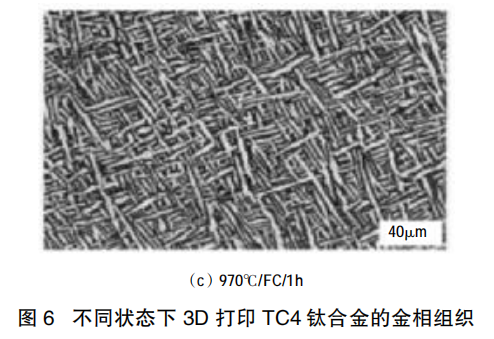

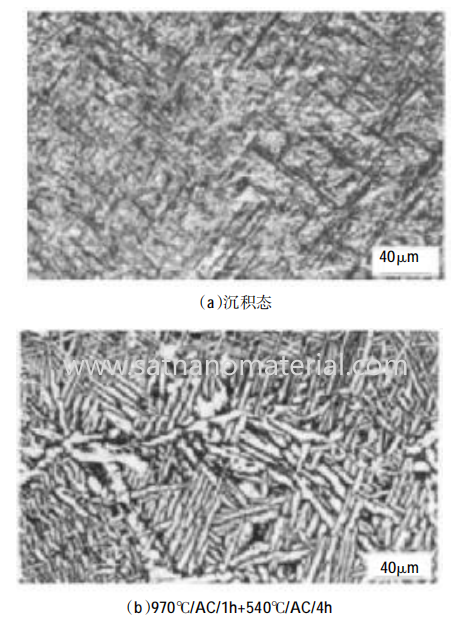

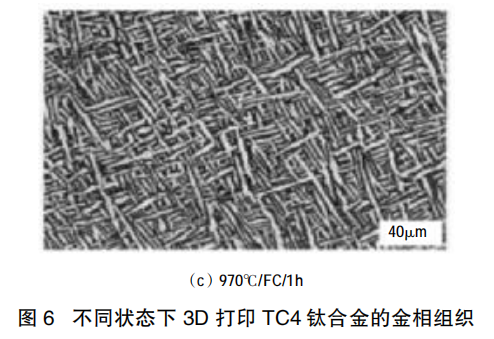

2.2.3 Solid solution and aging heat treatment Figure 6 shows the metallographic structure of TC4 alloy in three different heat treatment states: as deposited (a), 970 ° C/1h+540 ° C/4h (b), and 970 ° C/1h (c). The deposited TC4 alloy has a mixed microstructure of alpha solid solution and beta solid solution; After heat treatment at 970 ° C/1h+540 ° C/4h (b), the metallographic structure transformed into a mesh basket structure; After further heat treatment at 970 ° C/FC/1h (c), the structure transformed into a bimodal structure consisting of a basket like structure and spheroidized alpha phase. Among them, the high-temperature creep performance, strength, and plasticity of the basket structure are good, while the plasticity of the bimodal structure is low and the strength is high.

Through analysis, it is known that solid solution and aging heat treatment can effectively improve the strength and plasticity of TC4 titanium alloy, but the cooling rate has a significant impact on the strength and plasticity of TC4 titanium alloy, and appropriate cooling methods should be adopted in production.

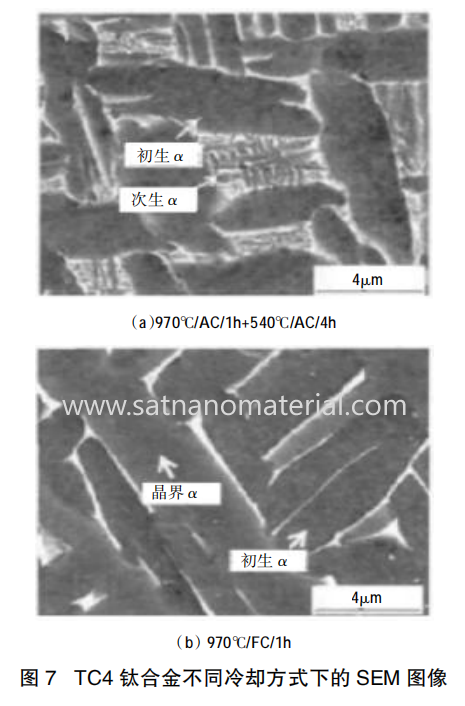

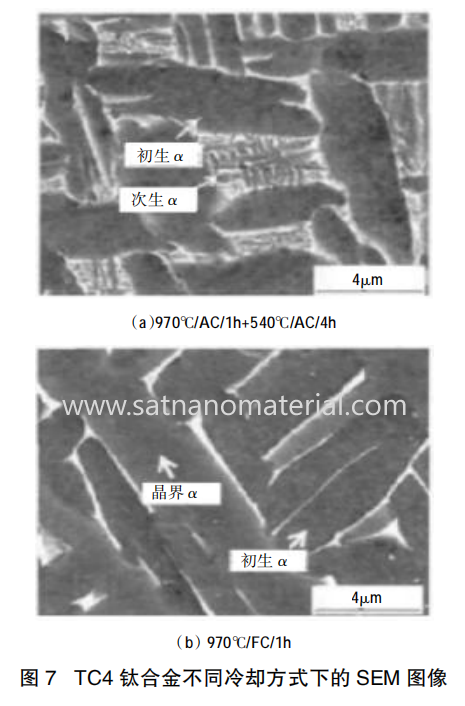

Figure 7 shows the microscopic images of the microstructure of TC4 titanium alloy mesh basket under different cooling methods. When TC4 titanium alloy is air-cooled, a semi diffusion phase transformation occurs. After solid solution and aging treatment, the β phase solid solution between the primary α phase solid solution will appear as small secondary α phase solid solution, as shown in Figure 7 (a); When TC4 titanium alloy is cooled in a furnace, diffusion type phase transformation occurs. After solid solution treatment, a bimodal structure is formed. The β phase solid solution between the primary α phase solid solution in the alloy does not produce secondary α phase solid solution due to the lack of subsequent aging heat treatment, as shown in Figure 7 (b); By comparison, it can be seen that under furnace cooling conditions, the grain boundaries and intragranular alpha phase solid solution are coarser than under air cooling conditions. When TC4 titanium alloy is subjected to external forces, cracks are more likely to initiate and propagate at the grain boundaries, resulting in reduced plasticity, and printing molding is not utilized.

Summary: (1) TC4 titanium alloy powder prepared by plasma rotating electrode method, (Tianjiu Metal can customize TC4 titanium alloy powder with different processes according to customer needs), the powder particle shape is very close to spherical, the surface is smooth, the flowability is good, and it has good powder characteristics, which meets the requirements of 3D printing.

(2) The microstructure of the cross-section of TC4 titanium alloy shows radiating columnar crystals from the temperature center to the edge, while the microstructure of the longitudinal section shows columnar crystals growing along the stacking layer direction. The control of heat source energy can effectively improve the microstructure of TC4 titanium alloy.

(3) The heat treatment method of solid solution+aging and air cooling effectively improves the strength and plasticity of the deposited TC4 titanium alloy, making its performance meet the requirements of TC4 titanium alloy 3D printing.

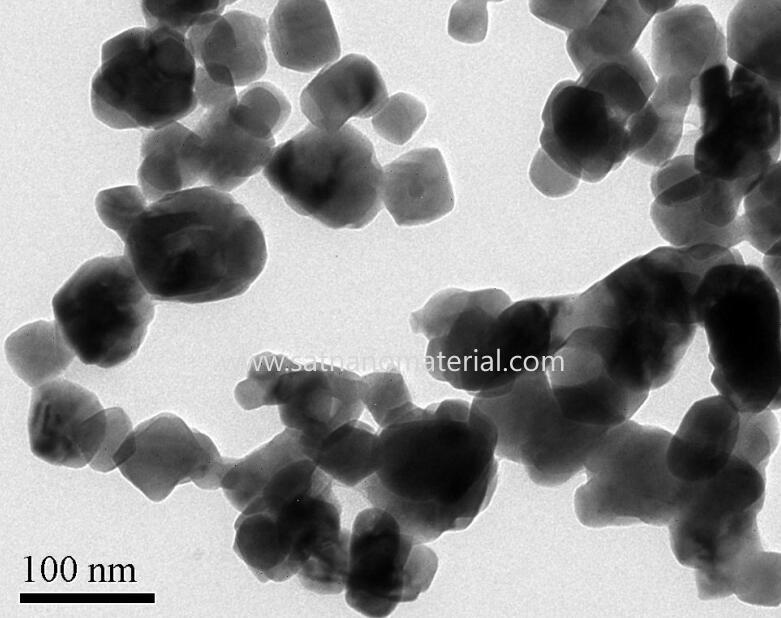

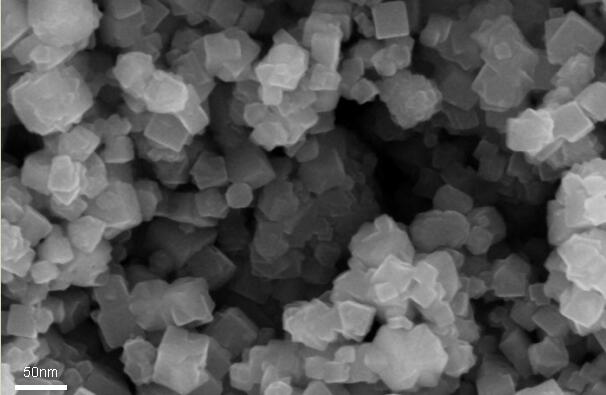

SAT NANO is a best supplier of TC4 alloy powder titanium alloy powder in China, we can offer 15-45um, 15-53um, 45-105um particle and other particle size, if you have any enquiry, please feel free to contact us at admin@satnano.com